The logistics and conveying industries are undergoing a rapid transformation, fueled by the rise of intelligent manufacturing, automation, and the ever-increasing demands for efficiency, precision, and adaptability. At the heart of this evolution lies a fundamental component: the gear motor. These powerful devices are not just simple power converters; they are critical enablers of sophisticated systems that underpin modern warehousing, distribution centers, and manufacturing plants. This article delves into the core role of gear motor principles in the intelligent manufacturing of logistics and conveying, exploring their applications, advantages, future trends, and how companies like MES-Drive are driving innovation in this space.

Traditionally, logistics and conveying systems relied heavily on manual labor and basic mechanical components. However, the advent of technologies like Artificial Intelligence (AI), the Internet of Things (IoT), and advanced robotics has ushered in a new era. Today’s logistics operations are data-driven, relying on real-time information to optimize workflows, predict demand, and minimize costs. Intelligent conveying systems, powered by these technologies, can dynamically adjust to changing conditions, route goods efficiently, and proactively address potential bottlenecks.

The e-commerce boom, exacerbated by recent global events such as supply chain disruptions and heightened consumer expectations for faster delivery, has further accelerated this trend. Warehouses are becoming increasingly complex, requiring sophisticated systems that can handle high volumes of goods with unprecedented speed and accuracy. This necessitates the utilization of advanced automation, and gear motors are central to this process.

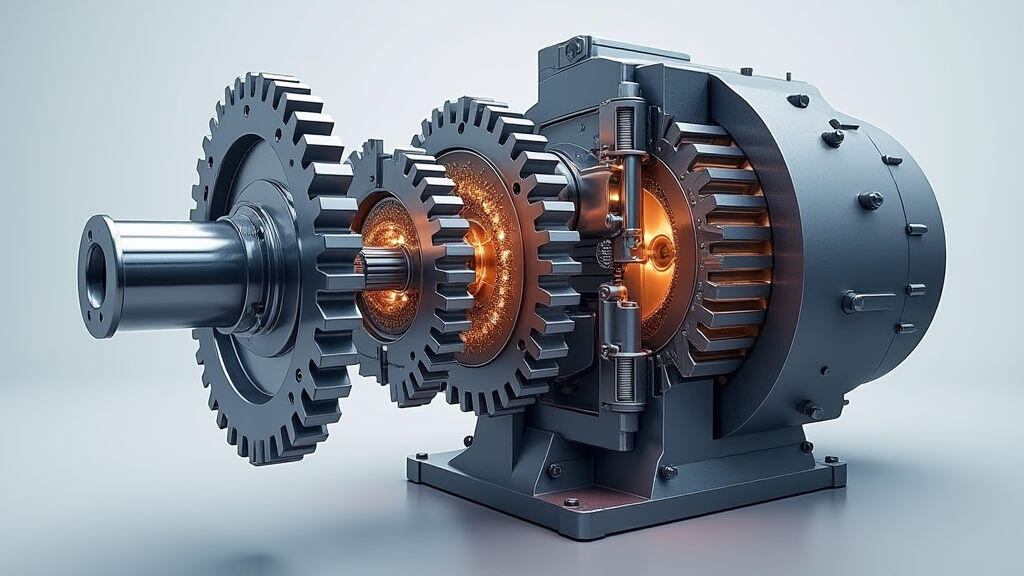

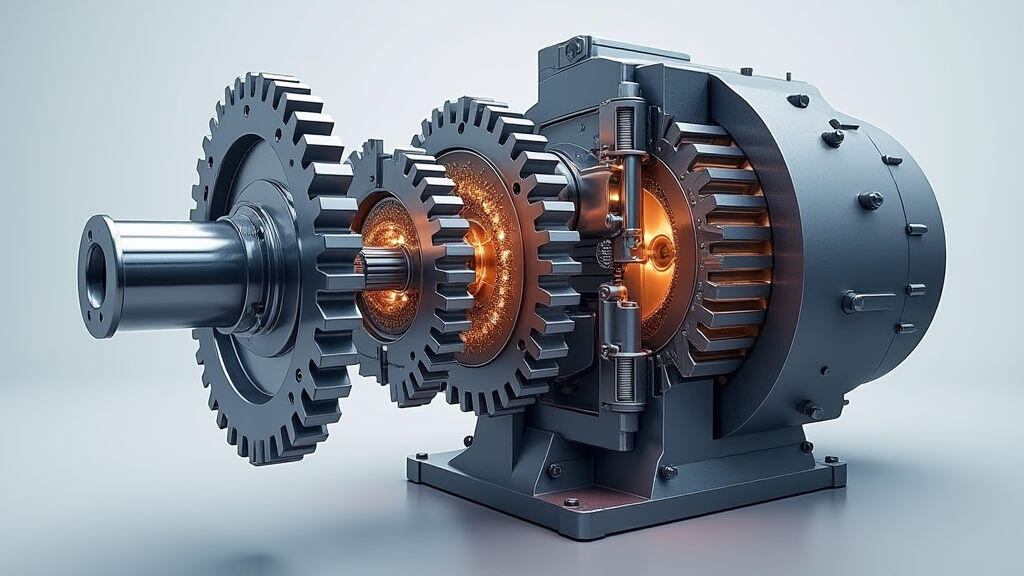

Gear motors essentially combine the functionality of an electric motor with a gearbox. The gearbox is the key to understanding their significance. It significantly alters the motor's output – reducing its speed while simultaneously increasing its torque. This torque multiplication is vital for driving heavy loads, such as conveyors carrying pallets of goods or robotic arms handling packages.

The principles behind gear motor operation are rooted in mechanical advantage. Different gear configurations (spur, helical, planetary, worm) offer varying levels of speed reduction and torque multiplication, each suited to specific applications.

The efficiency of a gear motor is paramount, especially considering the continuous operation often required in logistics environments. Improvements in gear design, lubrication systems, and motor technology are constantly pushing the boundaries of efficiency, helping to reduce energy consumption and operational costs.

The applications of gear motors in intelligent logistics and conveying systems are vast and diverse:

The future of gear motor technology is inextricably linked to the advancement of intelligent manufacturing. Several key trends are shaping the industry:

MES-Drive is at the forefront of these advancements, developing high-performance gear motors with integrated IoT capabilities and AI-powered control systems specifically tailored for the needs of intelligent logistics and conveying. Their commitment to innovation ensures that customers have access to the most advanced gear motor technology available.

Gear motors are far more than simple power converters; they are integral components of the intelligent manufacturing revolution in logistics and conveying. Their ability to provide precise torque, efficient power transmission, and seamless integration with advanced technologies makes them essential for building modern, efficient, and adaptable systems. As AI, IoT, and robotics continue to reshape the industry, the role of gear motors will only become more critical. Companies like MES-Drive are leading the charge in developing next-generation gear motors that are driving innovation, improving efficiency, and shaping the future of logistics. The increasing focus on supply chain resilience and the drive for faster, more sustainable delivery will only amplify the demand for these critical components. Therefore, understanding and leveraging the capabilities of gear motors is paramount for organizations seeking to thrive in this rapidly evolving landscape.

Leave A Reply

Your email address will not be published. Required fiels are marked